Ensuring Eligibility and Compliance with EASA & FAA Regulations

Proper installation of aircraft parts is a critical aspect of maintaining airworthiness, safety, and regulatory compliance within the aerospace industry. Both the European Union Aviation Safety Agency (EASA) and the Federal Aviation Administration (FAA) have established rigorous standards and regulatory frameworks that govern the entire process of installing parts on aircraft. Maintenance organizations and technicians must thoroughly understand these requirements to ensure that all installed components meet legal and technical criteria.

Regulatory Foundations: EASA Part-145 & FAA 14 CFR Part 43

Under EASA Part-145, maintenance organizations are required to implement quality systems, employ qualified personnel, and maintain detailed records for all maintenance, repair, and installation tasks. Similarly, FAA regulations 14 CFR Part 43 and Advisory Circular AC 43.13-1B provide detailed guidance on acceptable methods, techniques, and practices for performing maintenance and installation activities.

Both agencies emphasize that no part may be installed without proper certification, traceability, and verification of eligibility. These frameworks ensure consistent airworthiness standards across civil aviation worldwide.

Understanding Eligibility of Aircraft Parts

Eligibility

is the cornerstone concept that determines whether a part is approved and suitable for installation on a specific aircraft model. Eligibility encompasses several factors:

Certification Status

Parts must possess valid airworthiness certificates such as FAA Form 8130-3 or EASA Form 1. These certificates confirm that parts conform to approved design data and airworthiness standards.

Source and Provenance

Components should be sourced only from approved manufacturers, repair stations, or suppliers holding appropriate approvals under EASA or FAA regulations.

Compatibility

The part must be compatible with the aircraft type, model, and configuration. This is verified through cross-referencing aircraft maintenance manuals, Service Bulletins (SBs), and Airworthiness Directives (ADs).

Condition and Serviceability

Only new, overhauled, repaired, or serviceable parts that meet technical standards may be installed. Parts showing signs of damage, corrosion, or wear that affect airworthiness must be rejected.

Traceability

Complete historical documentation regarding the part’s manufacture, maintenance, and ownership history must be maintained and accessible.

Failure to verify eligibility can lead to regulatory violations and compromise flight safety.

The Importance of Form 1 and Equivalent Documentation

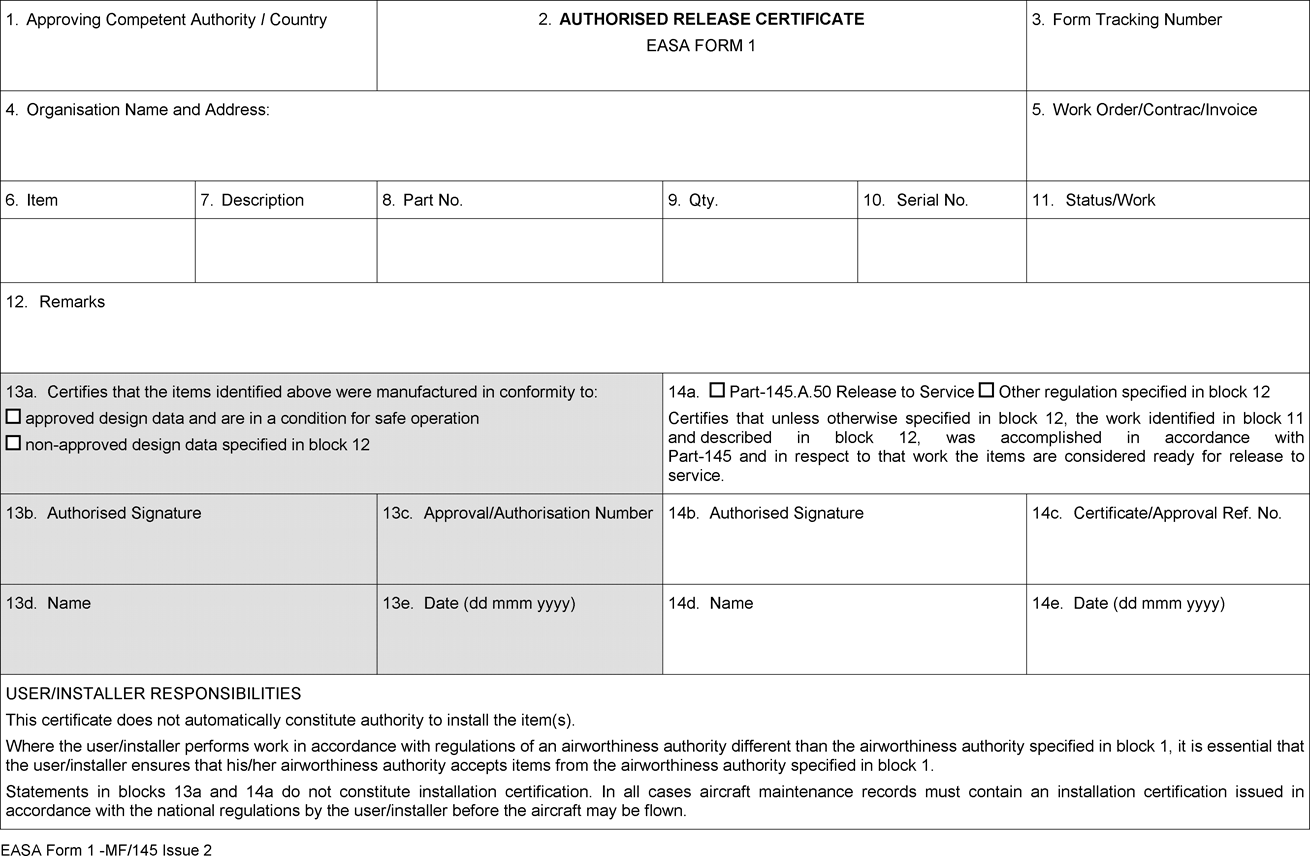

FAA Form 8130-3 (Authorized Release Certificate, commonly known as Form 1) and EASA Form 1 serve as essential documents certifying the airworthiness and conformity of aircraft parts.

These forms detail crucial information including part numbers, serial numbers, description, manufacturer, and the status of conformity.

Issued by authorized organizations or individuals, they legally attest that the part meets regulatory and design requirements.

Both forms support traceability and are mandatory for parts installation on certified aircraft.

Installation without valid Form 1 documentation is non-compliant and invalidates the airworthiness status of the aircraft.

Qualified Personnel and Training

Installation must be conducted by personnel holding valid licenses or certificates under EASA Part-66 or equivalent FAA certifications. Technicians should:

Be trained and authorized for the specific aircraft type and system.

Have access to and understand OEM manuals, SBs, ADs, and regulatory requirements.

Follow company quality assurance procedures and maintain currency on industry best practices.

This ensures installation is performed with technical precision and regulatory compliance.

Adherence to OEM Installation Procedures

Manufacturers provide detailed Original Equipment Manufacturer (OEM) manuals which specify:

Installation sequences

Torque and fastening specifications

Calibration and adjustment steps

Approved tools and equipment

EASA and FAA require strict compliance with these instructions. Any deviation must be pre-approved by the relevant authority and documented to preserve safety and compliance.

Documentation and Record-Keeping

Complete and accurate documentation is a regulatory obligation. Records must include:

Details of installed parts including certified Form 1 references

Work performed, date, signatures of authorized personnel

Entries in aircraft logbooks documenting installation activities

These records ensure traceability, support regulatory audits, and maintain the continuous airworthiness of the aircraft.

Inspection, Testing, and Return to Service

Post-installation, rigorous inspections and functional testing are required:

Visual and physical inspection to confirm correct installation

Functional tests as prescribed by OEM and regulatory guidelines

Systems integration checks to verify correct operation within aircraft systems

Only after successful completion of these steps can the aircraft be returned to service under both EASA and FAA regulations.

Conclusion

Installation of aircraft parts governed by EASA and FAA regulations is a meticulous process demanding:

Verification of eligibility to ensure parts are certified, compatible, and serviceable

Use of properly issued Form 1 documentation for traceability and airworthiness certification

Skilled and licensed personnel performing installation in strict accordance with OEM manuals

Comprehensive documentation and post-installation testing

Adhering to these standards protects the safety of flight operations, maintains regulatory compliance, and preserves the integrity of the aerospace industry.